FLARE GAS MODIFICATION

Alexandros, Inc. (ALEXANDROS), via our United States service providers, utilizes a PROPRIETARY CHEMICAL PROCESS to REMOVE IMPURITIES from WASTE GAS PRODUCED by OIL & GAS EXTRACTION.

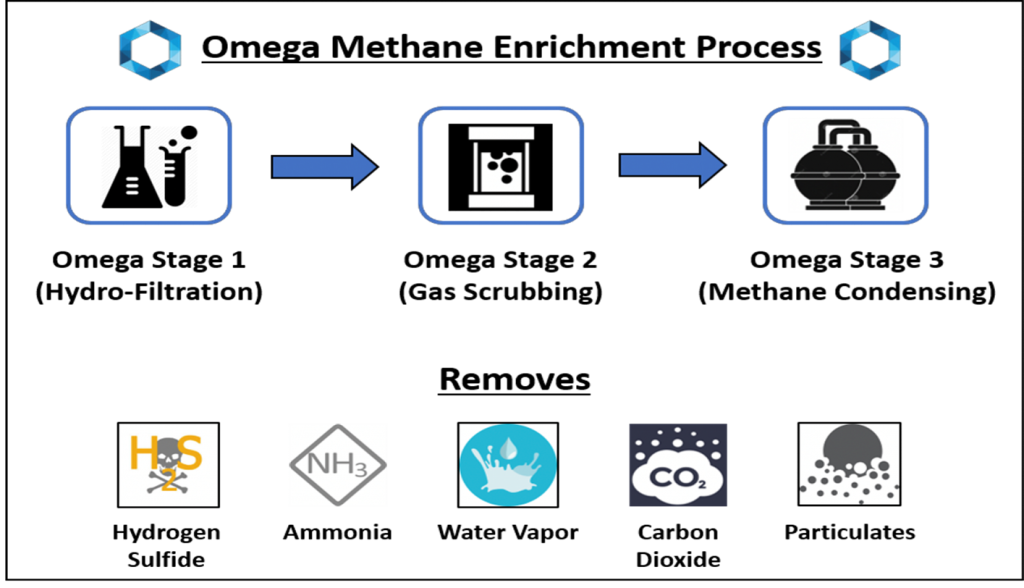

Our MULTI-STAGE SYSTEM REMOVES CONTAMINANTS such as hydrogen sulfide, carbon dioxide, and water vapor leaving behind refined methane. By lowering the impurities in the methane, our system can produce commercially marketable natural gas. Frequently, the gas produced by fracking activities is of such poor quality that it is simply burnt off as flare gas.

This process wastes a potentially valuable and environmentally sound commodity. Onsite, the gas can be used for producing electricity or heat needed in other operations or processes. Also, by burning a cleaner gas, producers release less contaminants into the atmosphere. These environmental impacts are increasingly under scrutiny by DOMESTIC and INTERNATIONAL GOVERNMENTS. ALEXANDROS can transform even the worst quality waste gas into a more readily refined and valuable commodity.

Easy Refinement: Initial processing by ALEXANDROS removes many of the contaminants that make refining methane gas a costly and time-consuming process. After processing by the ALEXANDROS system, the produced gas is free of contaminants and will burn at a uniform rate and temperature. Contaminants removed by ALEXANDROS include but are not limited to: Hydrogen Sulfide, Volatile Organic Compounds, Heavy Metals, Carbon Dioxide, Water Vapor, Particulates, and Ammonia. Removal of these corrosive elements help preserve follow-on refinement and transportation equipment.

Hydrogen Sulfide: The most dangerous and significant impurity in waste gas mixtures is hydrogen sulfide. The ALEXANDROS enhancement process removes hydrogen sulfide from raw gas mixes. Hydrogen sulfide presents a significant health risk to workers and strict regulations govern acceptable levels. The removal of hydrogen sulfide and other sulfur compounds also makes the raw product safer for transportation.

Water Vapor and Carbon Dioxide: Other factors adversely affecting the price and quality of the are the water vapor and carbon dioxide content. These gases, while not hazardous, affect the combustion of a gas mixture even in relatively low quantities. Water vapor also condenses in gas equipment and can cause corrosion. Natural gases with minimal waste products like water and CO2 are much easier on processing equipment and command much higher prices on the market.

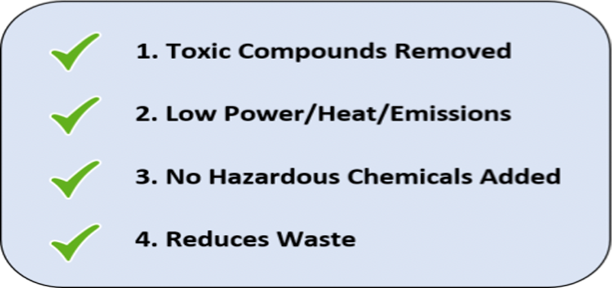

Environmentally Responsible: ALEXANDROS employs extraordinary measures to provide the most ecologically sustainable solutions. In contrast to other processes, ALEXANDROS systems use very little power, do not require additional heating, and produce no harmful emissions. All the contaminants are locked in a geopolymer base for safer removal and disposal. The substances used in the process are all naturally occurring, non-toxic, and organic.

Scalable and Modular: Our ALEXANDROS processing units can be built to handle any volume of gas refinement. ALEXANDROS systems can be mounted on mobile trailers or emplaced at a fixed site as needed. ALEXANDROS solutions are flexible, custom- designed platforms that perform in the most demanding environments.

Process Overview: ALEXANDROS utilizes a three-step process to enrich the rough waste gas into refined methane. The first step is ALEXANDROS’s proprietary hydro filtration stage which removes the CO2, any fine particulates, and most water vapor. The second step is the gas scrubbing phase where the remaining gas flows through scrubber canisters. The scrubber compounds are specifically formulated to bond with unwanted contaminants and lock them in place. Lastly, the refined methane is condensed into a pressurized vessel for transport. An additional cryogenic stage can then be implemented to convert the compressed natural gas into liquified natural gas to reduce the total volume by 600%.

The diagram below illustrates the geopolymer base for safer removal and disposal. The substances used in the process are all naturally occurring, non-toxic, and organic.

HIGHLIGHTS: Mobile, modular and scalable and can be centralized with smaller systems integrated into the periphery. Hub and Spoke are designed for 24×7 operation w/ remote monitoring. The design removes but is not limited to H2S, Co2, H2O, Heavy Metals, Mercaptans, Ammonia, Nitrogen, and BTEX from the flare gas stream. This process produces a high purity of refined methane for CNG and/or LNG Markets. The process does not require Glycol injection and does not require heat.